| Type | Traction vertical conveyor | Chain vertical conveyor |

| Car dimension | Customized according to freight dimension | |

| Rated load |

500-10000kg | 500-3000kg |

| Rated spped | ≤90m/min | ≤60m/min |

| Lifting height | ≤40m | ≤20m |

| Driving mode | PLC(Imported Brand) | |

| Host mode | Permanent magnet synchronous gearless motor | Asynchronous motor |

| Driving control | VF vector control | V/F control |

| Driving mode | Steel wire rope | Chain |

| Positioning mode | Sensor + Encoder | Sensor |

| Positioning precision | ≤±3mm | |

| Power supply mode |

Three-phase Five-wire AC380V 50Hz | |

| Load (kg) |

Lifting height (m) |

Speed (m/min) |

||

| 40 | 30 | 60 | 90 | |

| 500 | ● | ● | ● | ● |

| 1000 | ● | ● | ● | ● |

| 1500 | ● | ● | ● | ● |

| 2000 | ● | ● | ● | ● |

| 2500 | ● | ● | ● | ● |

| 3000 | ● | ● | ● | ● |

| 3500 | ● | ● | ● | ● |

| 5000 | ● | ● | ● | |

| 10000 | ● | ● | ||

| Load (kg) |

Lifting height (m) |

Speed (m/min) |

||

| 20 | 30 | 40 | 50 | |

| 500 | ● | ● | ● | ● |

| 1000 | ● | ● | ● | ● |

| 1500 | ● | ● | ● | ● |

| 2000 | ● | ● | ● | |

| 2500 | ● | ● | ● | |

| 3000 | ● | ● | ||

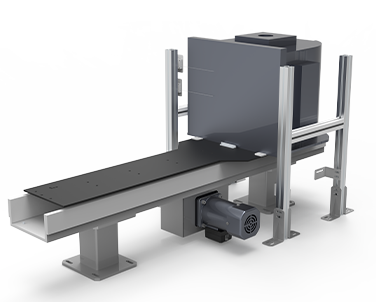

Chain vertical conveyor product: lifting height within 20 m, lifting speed

within 60 m/min, load within 3000 kg;

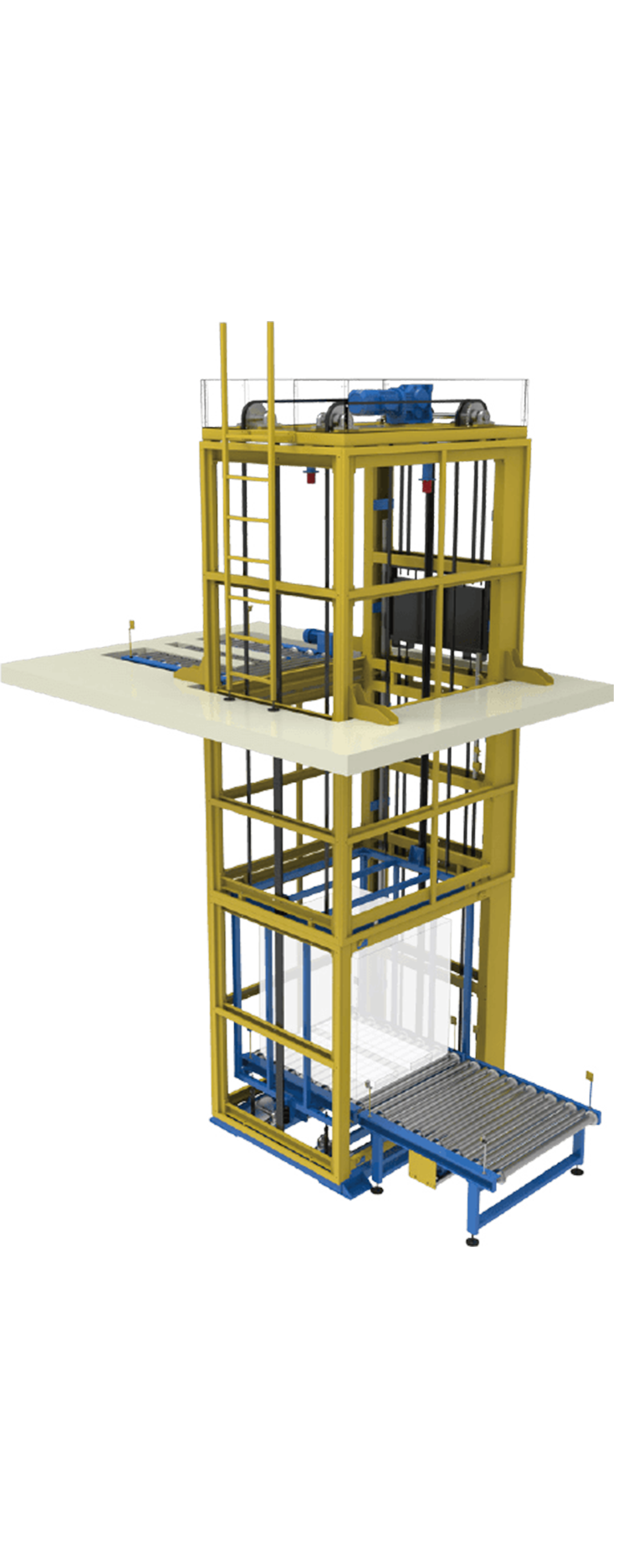

Traction vertical conveyor product: lifting

height within 40 m, lifting speed

within 90 m/min, load within 5000 kg; Can customize products with higher specifications

according to customers' needs.

No need for acceptance and annual inspection of special equipment, only need to maintain it regularly according to the product instructions.

For low-temperature cold storage, clean factories, and new energy material factories, perfectly match various needs.

For the hardware aspect, vertical conveyor can connect to various regular

transportation lines of the landing such as roller and chain and can also connect to

flexible handling equipment such as AGV and smart forklifts.

For the software aspect,

it supports mainstream industrial bus protocols such as

ModBus RTU and ModBus TCP, etc.

Sill clearance is 5-8 mm between the car and the landing. For AGV with small wheel diameter, fewer bumps and more stable operation.

Can be equipped with steel structure according to customers’ requirements, no

need concrete shaft, very little dependence on constructions.

Can be installed at any

location of the workshop according to the actual

production process requirements, only need to open holes in the plates of each floor to

install.

Entrance and exit of each landing can be set according to actual production process requirements, Can be configured with various conveyors and other horizontal transportation devices according to the types of goods.

Communication protocol supports upper software controls such as SCADA and WCS,

etc. and supports manual HMI operation.

Can achieve independent operation of the

vertical conveyor and linkage operation

between conveyors and other equipment.

Complete safety protection measures such as full load and overload detection, broken rope and chain detection, etc., to ensure the safe operation of the equipment.

Square welded steel pipe, surface electrostatic powder coating

Chain conveyor uses precise gear speed reducer + Asynchronous motor, silent and

energy-saving;

Traction conveyor uses permanent magnet synchronous gearless motor, big

starting

torque, no need maintenance.

The drive shaft and sprocket of the chain conveyor are made of 45# steel, which

is quenched and tempered after being machined (with normalizing at 850°C and annealing at

400°C), surface hardening blackening treatment;

The traction conveyor uses a

multi-groove steel traction sheave with V-shaped

cut grooves, providing sufficient friction for the steel wire rope while extending its

service life.

The drive shaft and sprocket of the chain conveyor are made of 45# steel, which

is quenched and tempered after being machined (with normalizing at 850°C and annealing at

400°C), surface hardening blackening treatment;

The traction conveyor uses a

multi-groove steel traction sheave with V-shaped

cut grooves, providing sufficient friction for the steel wire rope while extending its

service life.

Elevator special T-section rail, large strength and high precision.

Elevator special guide shoe, large strength, no balanced loading, endurable and wear-resistant, not easy to generate dust, safer and more stable.

When any chain breaks, the equipment will immediately sound an alarm and stop operation.

Governor detects the moving speed of the car, and pulls the safety gear to lock the guide rail when car runs down over speed, ensuring that the car cannot fall over speed.

Reliable operation, abundant communication interfaces, can be linked with AGV, transportation lines, flexible docking with MES, SCADA,WCS and other systems.

Control speed and acceleration, make operation curve more stable, eliminate the impact on the system during the start and stop process, extend the service life of the equipment, and at the same time make the transported goods safer.

When any chain/ rope breaks, the equipment will immediately sound an alarm and stop operation to avoid accidents.

The front hall door is equipped with an automatic fast speed door, automatic opening when car arrives, automatic close after finishing goods transportation. PVC and clean materials are optional.

Gear Governor detects the moving speed of the car, and pulls the safety gear to lock the guide rail when car runs down over speed, ensuring that the car cannot fall over speed.

Governor detects the moving speed of the car, and pulls the safety gear to lock the guide rail when car runs down over speed, ensuring that the car cannot fall over speed.

German technology, precise helical - bevel gear speed reduction motor, compact structure, long service life, efficient and eco-friendly.

Carry out hazard warning and monitoring of the length, width and height of the goods through photo-electric sensors to realize safe automatic running.

Achieve car continuous monitoring at any location in the shaft, more accurate positioning. Suitable for special application scenarios such as high lifting height and forklift.

Car can detect the weight of the goods, sound an alarm when the limit is exceeded, and the system stops operating to avoid risks, ensure equipment safety and extend the service life.

Horizontal transportation devices such as telescopic fork, roller conveyor or chain conveyor are installed in the car according to customers’ requirements and the transportation devices are equipped with brake device to avoid the unexpected horizontal movements of the goods during the lifting process.